Precision

The production of components is generally subject to tolerances. Already during the development of the component, it is therefore necessary to define manufacturing and position tolerances that represent a reasonable compromise between functionality and costs.

Following production, the checking of tolerances is an elementary component of quality assurance. In addition to conventional methods of measurement, 3D scanning is becoming increasingly important. Not only can individual dimensions be measured, the 3D scanner is much more capable of capturing the entire geometry of the component with high precision.

Tolerance Analysis

With an assembly consisting of several parts, the overview of the effect of tolerances is quickly lost. Tolerance analyses are the means to get this overview back. All combinations of tolerances are considered.

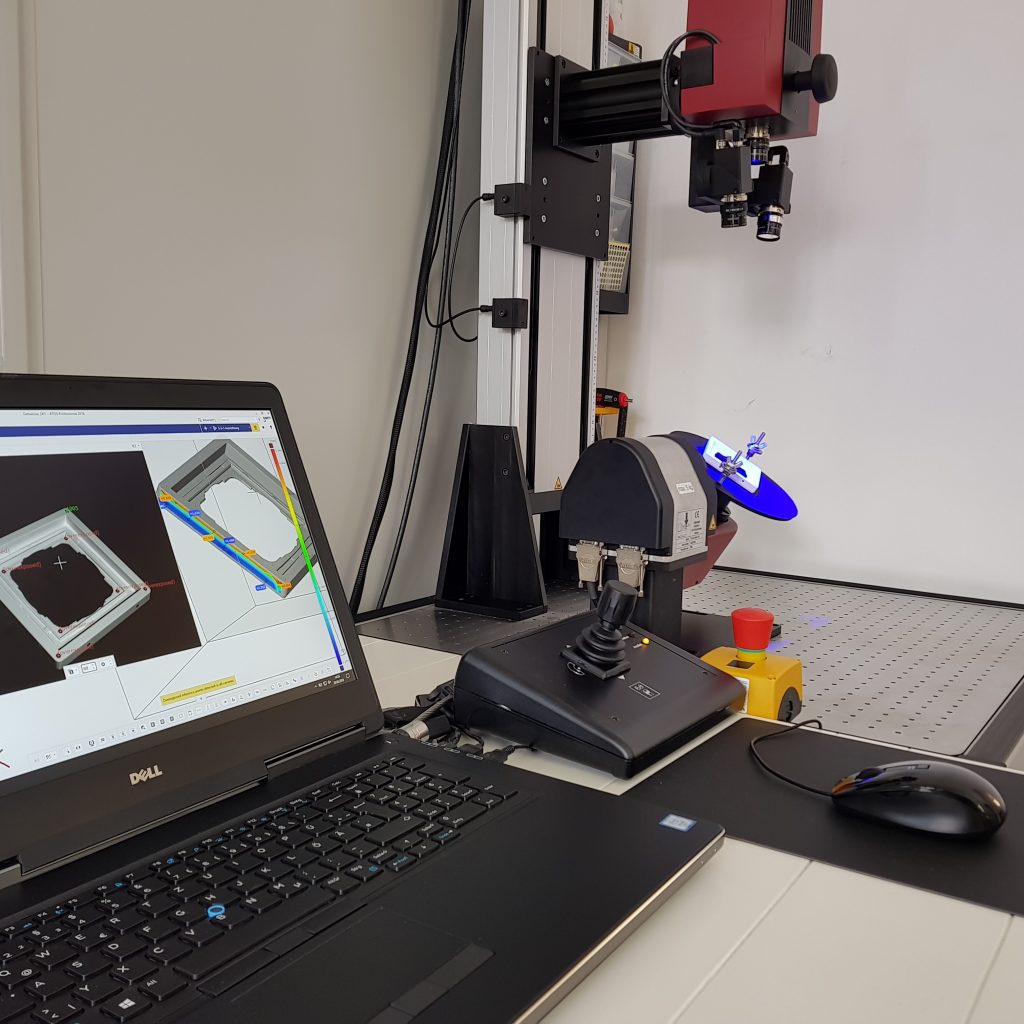

3D Measuring

With our 3D scanner, components can be measured with high precision and the results are displayed in a comprehensive presentation. This allows quality control with unprecedented precision.

But the 3D scanner can also be used for reverse engineering. The scan delivers a model which can be converted to a CAD part via reverse engineering.

Prototyping

A prototype is important for the development process in many ways. Holding a component in your hand for the first time provides important insights that the virtual model does not offer.

This is because a prototype offers the opportunity to test functions and processes, such as assembly. Depending on the type of prototype, statements can also be made about its durability.

High Speed Film

With our high-speed camera, tests can be observed in our inspection laboratory. Processes that only last a few milliseconds are still recorded and can be evaluated.