Integrated Product Development

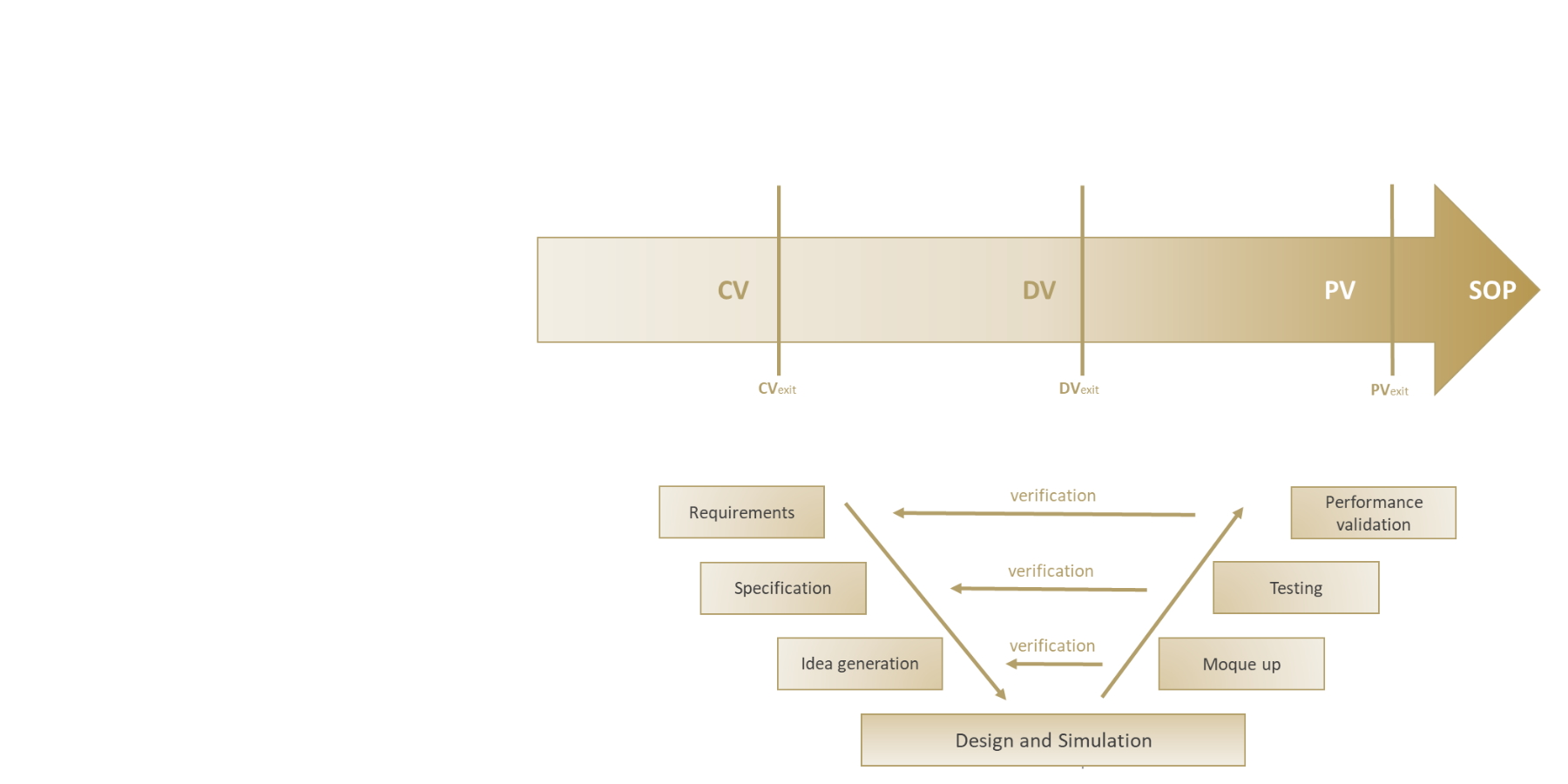

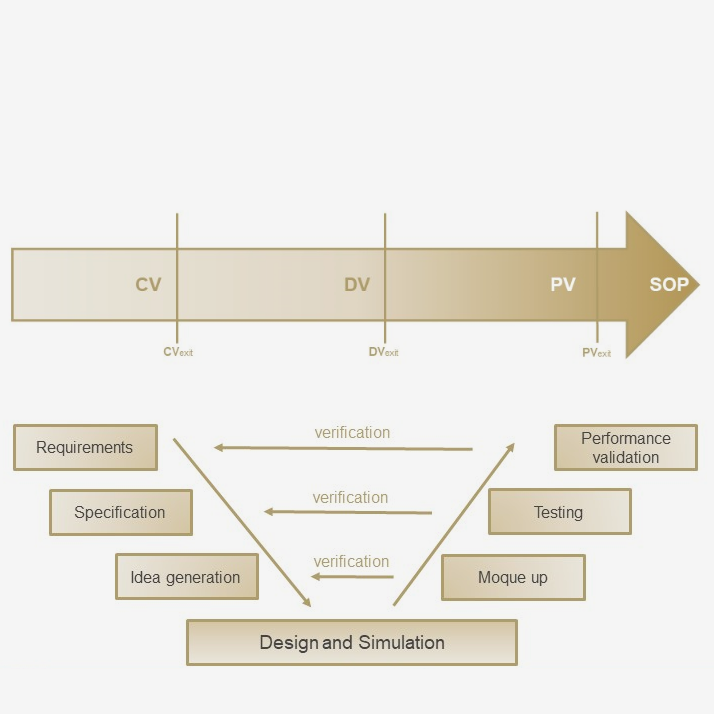

Every good product needs a good idea. But the good idea is only the beginning of the product development process. Good and efficient product development requires expertise, experience, knowledge of materials and manufacturing processes, a good network of suppliers and specialists and the ability to correctly assess risks at an early stage.

The Idea

The product development process starts with your idea and already at this point we can provide valuable support. Even at the idea stage, it is important to think about the materials, production processes and functionality of the later product. Thanks to many years of experience, we are able to assess what is suitable for your product right from the start. This allows us to reduce costs enormously, because expensive changes at later development times can be avoided.

The Implementation

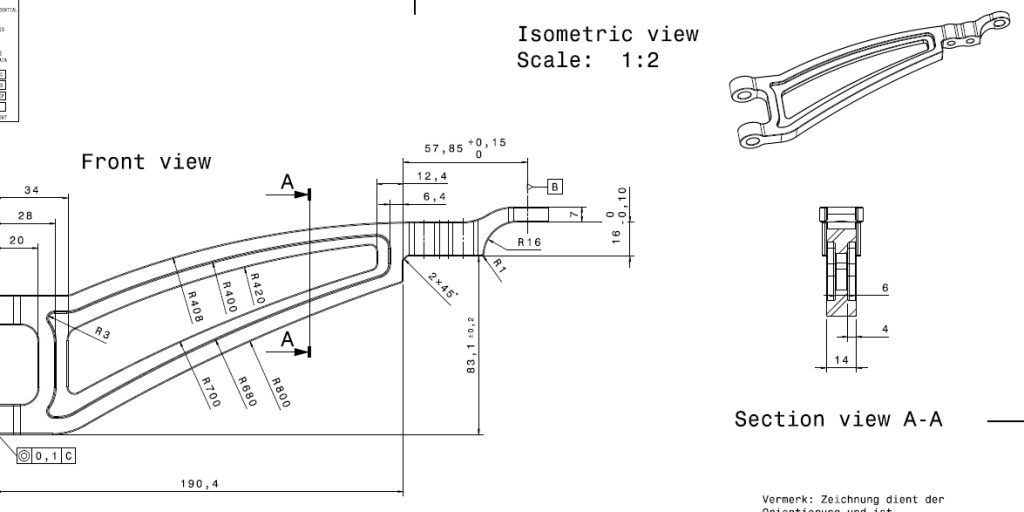

The development and construction is based on our 3D CAD and CAE systems such as CATIA V5 or SolidWorks. Through virtual development, problems can be identified and solved before the first prototype is created. This saves time and money.

During the design phase, we select a production method for each component and design it accordingly. This simplifies the step from the prototype to the serial part.

Our continuous project documentation ensures that you always have the overview of your project!

The Testing

Once the development is finished, drawings are derived from the components, tolerance analyses and DFMEA are carried out and the first prototypes are created. With these prototypes we carry out functional tests in our own or external laboratories.

Ready for Serial Production

There is still a long way to go from a prototype to serial production. With the help of our well-established processes, we will guide your product to the series part in a goal-oriented manner.

The knowledge gained from prototypes and tests is just as much a part of this as production processes, quality and cooperation with suppliers.

Through our experience in global development projects we have learned to take local needs, requirements and capabilities into account when implementing the products.

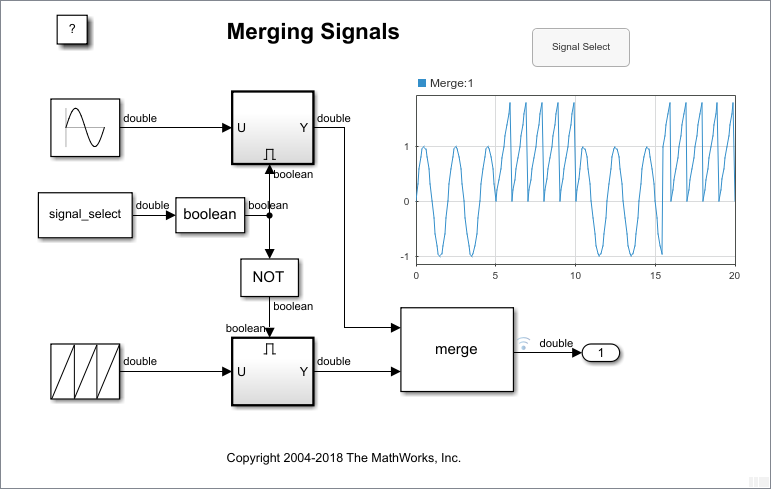

Matlab/Simulink

With Matlab/Simulink, complex simulations can be carried out entirely virtually at an early stage of development, when changes to the system can still be realized easily and economically.

Quality Assurance

Following production, the checking of tolerances is an elementary component of quality assurance. In addition to conventional methods of measurement, 3D scanning is becoming increasingly important. Not only can individual dimensions be measured, the 3D scanner is much more capable of capturing the entire geometry of the component with high precision.

Prototyping

A prototype is important for the development process in many ways. Holding a component in your hand for the first time provides important insights that the virtual model does not offer.

This is because a prototype offers the opportunity to test functions and processes, such as assembly. Depending on the type of prototype, statements can also be made about its durability.

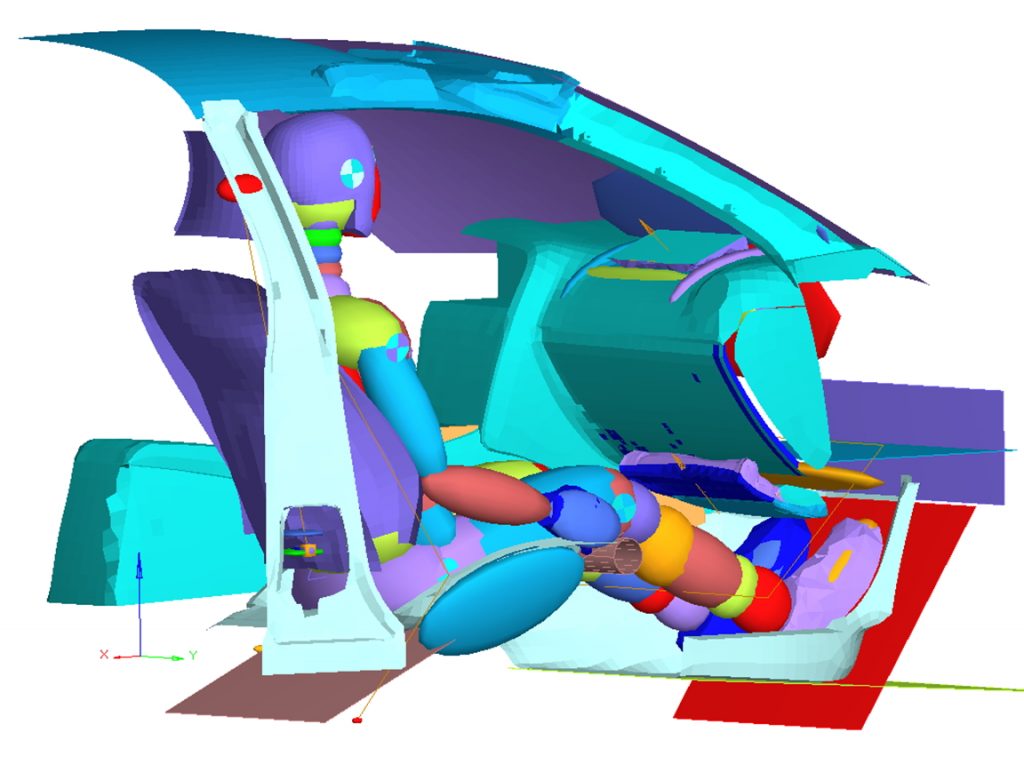

Simulation

By integrating simulations into the development process at an early stage, costs can be effectively reduced by preventing expensive changes to the product in a later development phase.

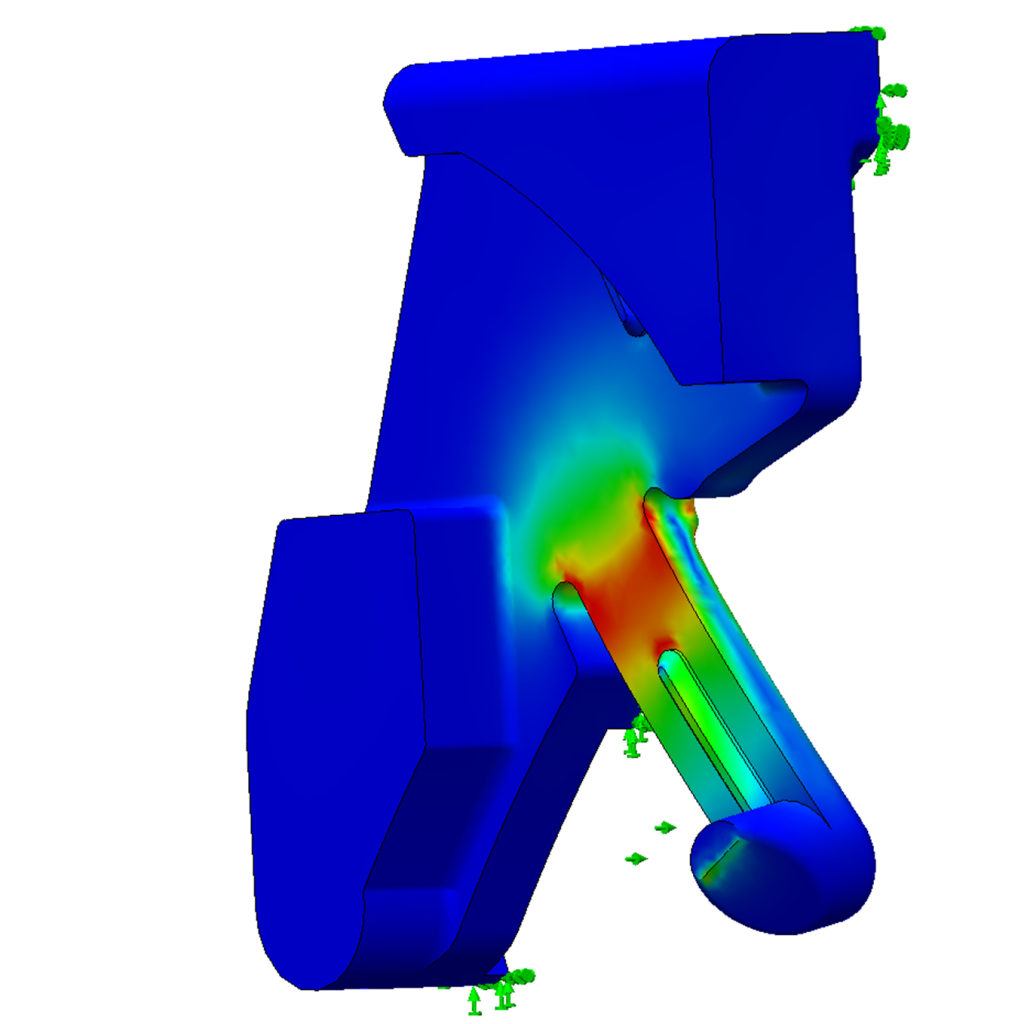

FEM

With the help of the finite element method, load cases on a component can be simulated virtually. The result of the calculation is the representation of the stresses occurring in the component. Various statements can be made from this simulation result:

- Does the component withstand the expected loads?

- At which points is the component overdimensioned?

Technical Drawings

The technical drawing is part of the daily work of an engineering office. Thanks to many years of experience, we can efficiently and precisely derive technical drawings from your components.

Network

With us as your partner, not only our know-how for your development process is at your disposal, but also the skills and knowledge of our network.

CAD/CAE

CAD and CAE programs such as Catia or SolidWorks build the core of our development process. These are not only used for standard design, but also for simulations such as FEM.

Tolerance Analysis

With an assembly consisting of several parts, the overview of the effect of tolerances is quickly lost. Tolerance analyses are the means to get this overview back. All combinations of tolerances are considered.